01.

Background

Altrans' The iProject award challenge 2014:

There are many little things we are surrounded by every day that we do not pay attention to. We are obsessed with big ideas, and idolizing their champions, but most big ideas come from little ones…

Let’s focus on a small thing with huge potential. A Cigarette butt! Yes, those little things that the streets are filled with and no one pays attention to.

Cigarette butt littering is not about smokers and the tobacco industry. It is a worldwide contamination issue, a toxic waste potentially diminishing our quality of life. And, interestingly enough, it is also a unique opportunity for innovation and value creation!

02.

How might we create value out of cigarette butt litter?

CBLP’s innovation goal is to develop new and unexploited recycling processes (I.P.) for the transformation of cigarette litter.

The major achievement of CBLP also should be to involve all the key players.

· The tobacco industry, Tobacconists and Retailers: Playing ahead of the environmental laws.

· Public Institutions: Setting up littering education and prevention campaigns, while reducing environmental impact costs.

· Waste management and concessionary companies: Improving the existing models and extending their sources for revenue generation.

· R&D: Creating opportunities for private companies and Universities open innovation collaborative developments and research.

· Consumers: Advocating for an environmental initiative and contributing to building awareness and changing littering behavior.

· Economic contribution through (I.P.) and added value materials.

03.

Solution

Yes! Cars made out of nanocellulose:

Whitepaper prototype with innovative solution that fits in the major industry areas with many possible applications for current and new Altran clients.

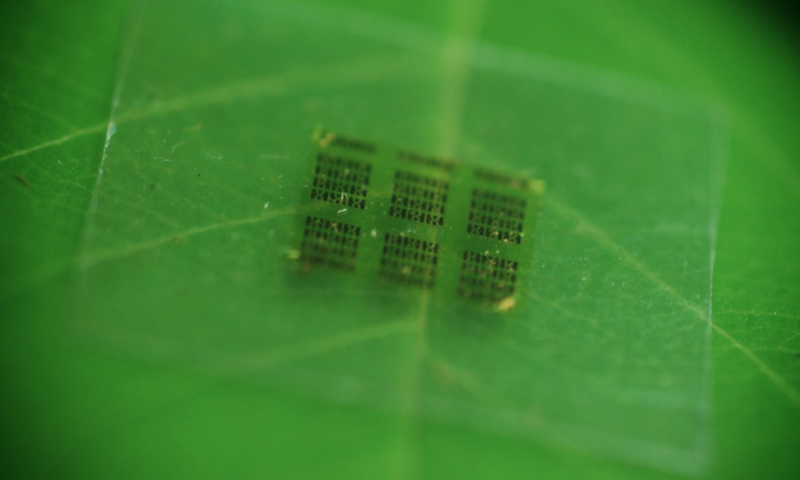

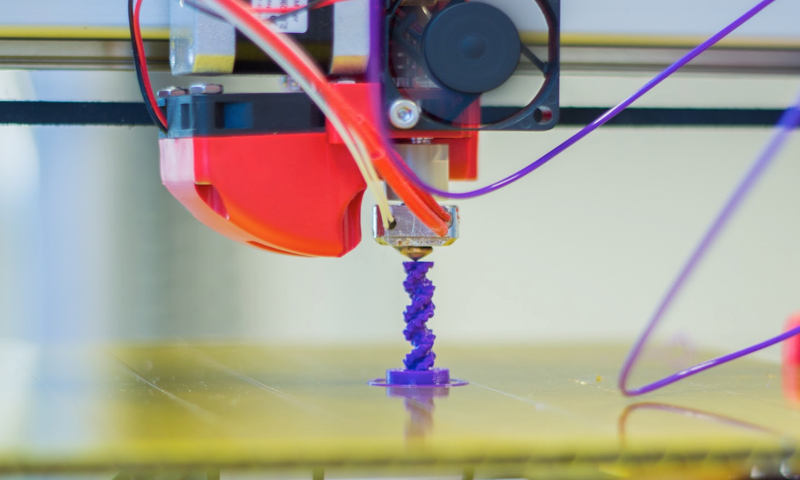

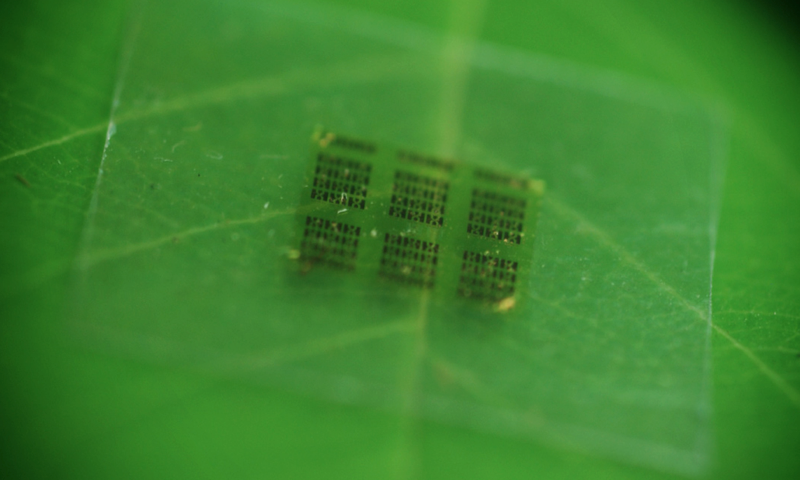

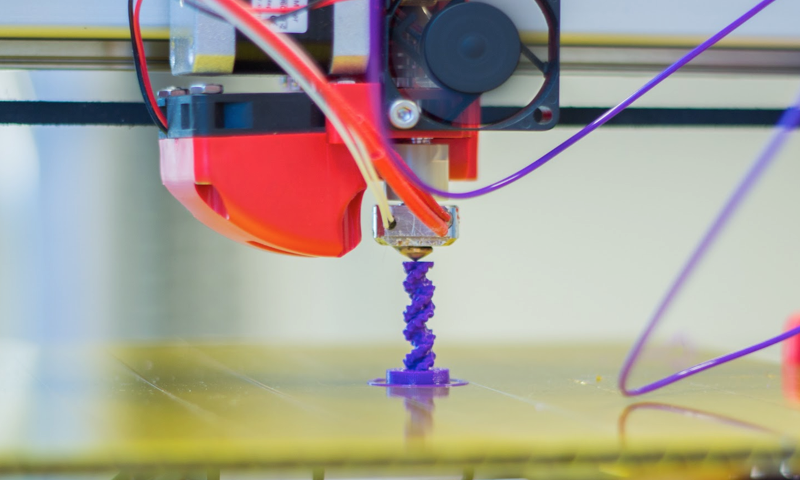

Nanocellulose strength-to-weight ratio is excellent for aerospace, automotive, military industries development, and also an alternative to plastic for 3D printing new polymers or computer chips.

Value Impact for Altran:

- Develop Nanocellulose out of cigarette butts.

The key added value CBLP project can bring to clients is making a high-potential material -with diverse and largely unexplored possibilities- commercially available worldwide, while delivering unique conditions for improving its current production processes.

-> Recyclable source, not depending on harvesting further forest biomass.

-> Reduced carbon footprint vs current production methods.

-> Production capacity, potentially reduced costs, and scalability.

-> Collecting Process Metrics.

Altran will largely benefit from its leadership in this initiative, pioneering the development of high-value materials technology through a unique process helping to solve a widespread threat to our environment to date. Contacts with key clients and institutions for the inception of the initiative will position Altran as a forward-thinking, forefront leader; while relations with prospective clients may generate business, not only through commercialization of the project’s direct outcomes, but also through further longer term partnerships aimed at exploring further uses of this and other similar new materials.